Something we often take for granted, toilets are simply incredible inventions. So, how is a toilet actually made? We reveal all…

When you think of engineering masterpieces, the humble toilet doesn’t immediately spring to mind. Yet, it is possibly one of the defining technological breakthroughs in the history of mankind. Indeed, the history of the toilet is truly fascinating (you can read our blog post to find out more!) and they’ve come a long, long way since the outdoor privies of the pre-war era.

As most toilets are made from ceramic, plenty of expertise and craftsmanship goes into making them, which requires careful production techniques and high quality raw ingredients. At Victoria Plum, all our toilets are manufactured to the highest of standards, which is why we’re pleased to be able to show you the whole process from start to finish.

Here is how a toilet is made

Step 1—Into the mould

The first step is moulding, where the raw ingredients are packed into a mould to form the shape of each toilet.

Step 2—Drying

Once removed from the mould, each product is dried thoroughly for a strong and solid construction.

Step 3—Glaze applied

After being thoroughly dried, each toilet is prepared for the glazing process. A shiny, hardwearing and easy-to-clean surface is added to every visible surface.

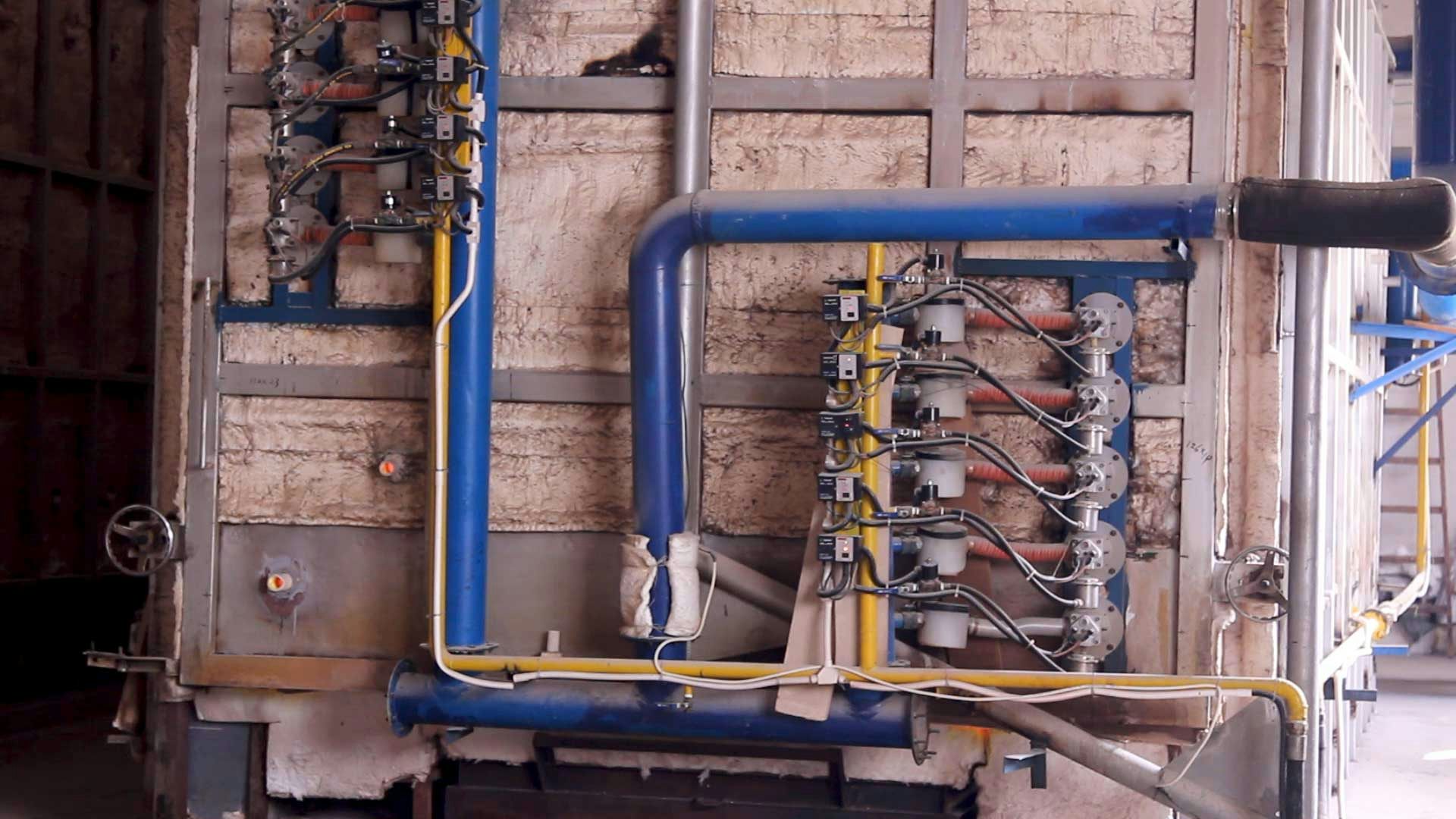

Step 4—Into the oven

Next, comes the heating stage. All toilets are put into a large oven, which reaches 1,220 degrees centigrade. To make sure each item heats evenly, a red dye is applied (this disappears during heating) which would show up any cold spots.

Step 5—Testing

A process of thorough testing and checking takes place throughout the process. This helps to ensure each product, as well as all materials, conform to our own rigorous standards.

Step 6—Polishing and packaging

Each finished toilet is then hand-polished and placed into secure packaging, ready and waiting for your order.

Shop toilets

So, now you’ve seen exactly how our toilets are made, why not browse our fabulous range? With a huge selection of designs and styles, from contemporary to traditional, simply click on the image below to begin.